MLD | FABRIC MOJO

At Mountain Laurel Designs, we push the boundaries in making outdoor gear stronger, lighter, and simpler. Specializing in the lightest, full-strength, ultralight, all-season gear means our fabric cost is often 3X to 10X those used on competing products. Why? Because we know the slightly higher upfront cost translates to value and performance in the field. Keep reading to learn what we use, and why.

BACKPACK FABRICS

Over the last 20 years we have offered or tested packs from almost every type of fabric: DCF, VX, Robic, Dyneema X, DX210d, etc. MLD was the first company to build and sell DCF backpacks in 2004.

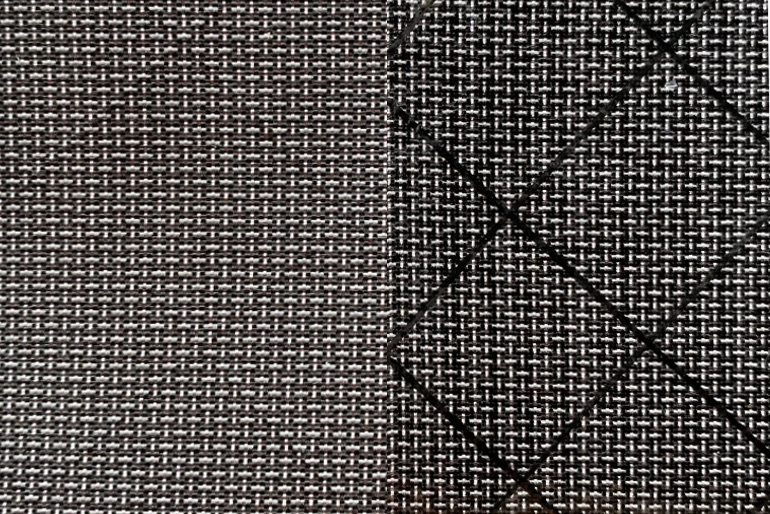

Outside woven face of the Ultra X (Left.) Inside laminate face with the X ply grid (Right.)

CHALLENGE ULTRA X ™ 200 & 100

Ultra X™ is 10X stronger than steel by weight. The high recycled content and expected extra-long service life of Ultra X™ 200/100 makes an excellent case for being one of the most advanced Eco-friendly ultra-light backpack fabrics available. Ultra fibers are the same chemical design type as similarly branded Dyneema and Spectra fibers.

Ultra X adds a 45 and 135-degree X ply of Ultra 200 fiber in a grid under the .75 RUV film. This adds strength and prevents diagonal stretch of the woven face fabric to enhance the longevity and strength of the waterproof RUV film layer to prevent delamination.

We use Ultra X 200 on the back and bottoms of the packs and Ultra X 100 on the sides and pockets. Pack side and shoulder strap pockets and other small gear accessories are made from the Ultra X 100.

- ULTRA X 200: 3.85 oz /sq yd

- ULTRA X 100: 3.26oz /sq yd

- ULTRA X is a woven blend of UHMWPE and 100% Recycled Polyester Fibers. The face fabric is woven 66% UHMWPE and 33% Recycled Polyester. The Inside X grid is Ultra 200 threads. It is backed by a .75mil RUV Recycled Film.

- ULTRA X Packs are Fully Seam Taped with Ultra reinforced TNT.

Ultra vs Ultra X: Ultra X adds the reinforcement X grid and increases the RUV film thickness. The X grid and RUV film increases the overall weight by only .35 oz/sq yd. Ultra X was specifically designed to reduce possible delamination in extreme use due to high diagonal stress.

ULTRA X 200 COMPARISONS

- Compared to 3oz DCF50, it’s 7X more abrasion resistant and 3X stronger.

- Compared to 5oz DCF150, it’s 6X more abrasion resistant 2.5X stronger.

- Compared to 6oz DP VX21, it’s 5X more abrasion resistant and 3.5X stronger.

- Compared to 4.5oz DX210d, it’s 4X more abrasion resistant and 3X stronger.

- Compared to 4.5oz Robic 210d, it’s 4X more abrasion resistant + 4X stronger.

- Ultra X seam tapes much better than DCF or VX for better water resistance.

ULTRA X 100 COMPARISONS

Ultra X 100 is only aboutin strength and abrasion 30% less than the Ultra X 200 comparisons. Super Strong and Super Light.

ECOPAK ULTRA TESTING

- We tested seam tape longevity and the RUV backing by multiple hot water washing machine cycles, long hot dryer cycles, as well as leaving it in the direct hot summer sun for many weeks.

- We measured the fabric’s surface heat retention via infrared thermometer against all other standard pack fabrics. They all measure the same for the same color.

- We sent multiple pack samples to highly experienced pro hikers to get feedback.

BACKPACK DESIGN NOTES

After over a year of testing and many hundreds of packs, we found that we could save a bit of weight and bulk using the Ultra X 200 for the pack back and bottoms and the lighter Ultra X 100 for the side, front and pockets. We feel the strategic combination of an ULTRA 200 + ULTRA 100 makes for the lightest full-strength frameless pack possible.

CHALLENGE ULTRAGRID IN BLACK BEAUTY, AVOCADO & CHILI

CHALLENGE ULTRAGRID ™

UltraGrid™ outperforms all similar-weight pack fabrics and is a great choice to save some bucks and get a great color vs. the tougher and more abrasion-resistant premium UltraWeave™ 200/400 fabric we offer.

UltraGrid™ is a woven, double RipStop, 80% 210d Recycled Nylon + 20% 200d Ultra UHMWPE material (Ultra High Molecular Weight PolyEthylene is +10X stronger than steel.) The double UHMWPE ripstop weave significantly increases the strength and abrasion resistance and lowers the overall weight vs. older single ripstop lower density type pack fabrics. Its superior strength, weight, and durability are why we’ve replaced the older 210d pack fabrics—like Dyneema X, DX210d, Extrema, Cordura, HDPE 210d Gridstop, Robic, etc.— with UltraGrid™.

UltraGrid looks awesome in Black, Avocado, and Chili colors. The two distinct white or black strands throughout the material are the UHMWPE, while the primary color is the Nylon. PU coated back has a 1,500mm Hydrostatic Head. CO DWR coated front contains no “forever” chemicals (fluorocarbons.)

UltraGrid™ nylon is recycled from post-consumer waste, contains no toxic PFCs, and is manufactured in a Bluesign Approved facility.

WEIGHT: 3.9 OZ / SQ YD | ABRASION: 1,100 Cycles | WATERPROOF: 1,500mm HH | TEAR STRENGTH: Does Not Tear

DCF (DYNEEMA® COMPOSITE FABRIC)

Starting in 2004, MLD is the oldest company to make and sell DCF backpacking gear. We developed many of the construction techniques and design standards.

Over the years, we have worked with every type of outdoor DCF fabric from .33oz sq/yd to 7oz+ versions. We have used DCF fabrics from .33 sq/yd to 1.5oz for shelters.

We now only use .8 DCF (Dyneema® Composite Fabric) (AKA: Cuben Fiber, DCF8, DCF .75, CT2e.08) in our shelters. It is strong, light, fully waterproof, and has a reasonably long service life. We also make a few small gear pieces in 1.5oz DCF (Dry Bags, Zip Sacks).

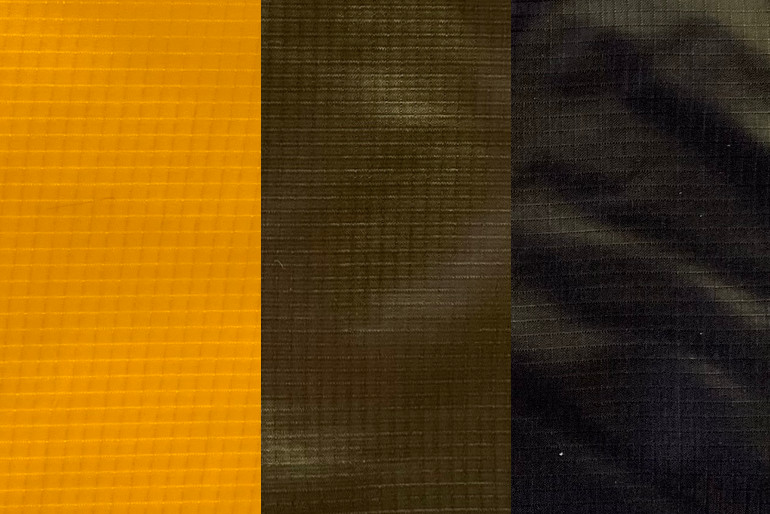

DCF .8 GREEN + DCF 1.5 WHITE

DCF SHELTER DESIGN NOTES

We specialize in All Season Shelters and no longer offer DCF shelters in the ever so slightly lighter and much more fragile .5 or .67 versions. Compared to .5 and .67 DCF, the .8 DCF is 2X stronger and offers a 3X longer service life.

We feel that now is the time in lightweight shelter evolution to shift emphasis away from the only (very) slightly lighter DCF versions to the longer service life and more Ecologically Sustainable .8 All Season DCF.

There has always been a debate on how to best construct DCF shelter seams. We use a special, permanent adhesive tape/glue with high levels of UV inhibitors on major seams. Our DCF tarp and shelter seams and ridgelines are bonded by a full 1″ overlapping seam (not sewn) for maximum strength and require no seam sealing. In over 15 years, we have never had a return due to a bonded main seal problem.

DCF shelters cost about 2X more than our 20d Pro SilNylon and weigh about 25-35% less. Built only by our highest skilled craftspersons, MLD has been building DCF shelters longer than any other company.

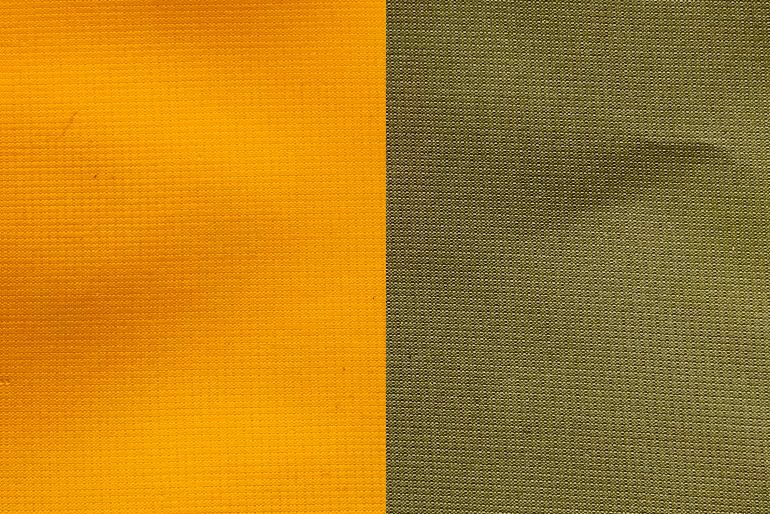

20D PRO SIL POLYESTER IN CITRUS ORANGE (LEFT) AND OD GREEN (RIGHT.)

20D PRO SIL POLYESTER

MLD Pro SilPoly 20D x 20D Micro RipStop is double-coated and impregnated with silicone on both sides for maximum strength and superior water resistance.

20dX20d = 1.4oz sq/yd: 5000mm+ Water Resistance

The higher HH rating ensures a very long service life. All silicone-coated tent fabrics can lose up to 50% of the HH ratings fairly quickly on the trail over a single thru-hike season. Start off with High HH = Stay with High HH.

It’s light, super-strong, and extremely waterproof.

SilPoly is highly valued for low stretch and tight tent+tarp pitches, especially when wet. It absorbs less water than almost all other non-DCF fabrics. We searched for years for a high-quality SilPoly that was both strong and low stretch, wet and dry.

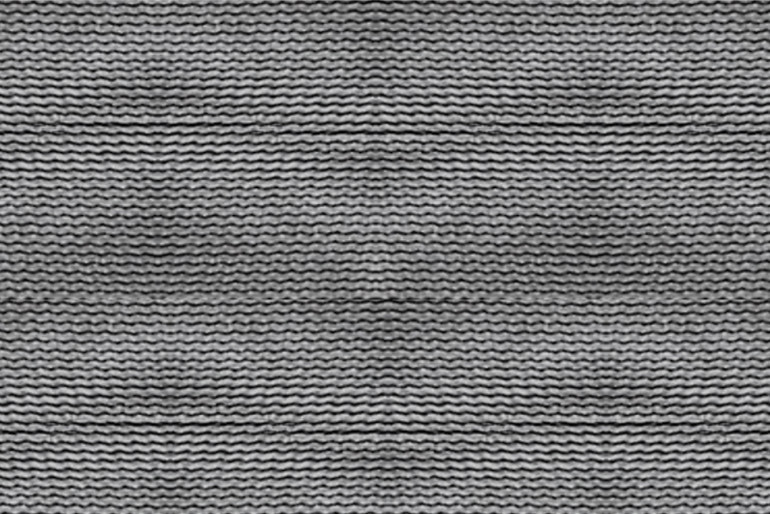

MOUNTAIN 10D x 10D RIPSTOP NYLON

MOUNTAIN 10D x 10D 3X DWR Ripstop (.72 oz sq yd | 26 gm sq m.) We tested about a hundred sub .8 oz sq/yd lighter weaves like 5D, 7D, 8D, and many 10D’s. We found most have significant drawbacks. Mainly with tear strength or stitch hole elongation. Our 10d has a very high-density weave vs. other generic 10d fabrics and is 2X stronger. Our 10d quilts can withstand many regular washing machine cycles. Just throw it in the washer and dryer like any synthetic garment.

High-quality DWR Coated Ripstop is more expensive and does add some weight – about 15% of the total finished weight in a sub 1 oz sq yd fabric. We only use the very best for long-term value for our customers in the field.

MOUNTAIN 10D CITRUS ORANGE, OD GREEN + BLACK

CLIMASHIELD ® APEX

Climashield® APEX is the highest warmth-rated continuous fiber synthetic insulation available for quilts. We selected a custom density for our quilts based on hundreds of user tests for a warmth factor to weight ratio that hit the perfect mark for functionality and lightweight.

Climashield® maintains loft better than down and any other synthetic in damp, wet conditions and can rebound from packing longer than other synthetics.

In very cold conditions, it is standard practice to use a light ClimaShield overquilt on top of a down bag to help prevent condensation from internal sources condensing in the down inner bag.

Climashield quilts sheathed in our Mountain 10d outer fabric hold up well after repeated compressions and washings.

eVENT ™

We use 15d x 15d eVENT™ 3 Layer Waterproof Breathable. The most breathable and functional, fully waterproof material available. The critical difference between this technology and traditional waterproof/breathable fabrics is the billions of microscopic pores built into the proprietary membrane that works instantly to vent water vapor (sweat) that builds up inside.

It’s called Direct Venting™ technology, and unlike other technologies, it doesn’t need to get wet to work. It’s a ‘dry system’ that allows eVent fabrics to be fully waterproof and fully breathable – keeping you as dry and comfortable as possible in the widest range of temperatures and conditions.

NANOSEEUM ™

Nanoseeum™ is the .7 oz sq/yd flame-retardant bug netting we use in all our shelter InnerNets and Bug HeadNets. Nothing gets through this screen! Nanoseeum’s fine mesh has extremely small holes that block even the smallest insects, including mosquitoes, gnats, flies, etc., but still allows for excellent ventilation. The tight weave also retains some heat and blocks a surprising amount of wind.

MLD TESTING + DEVELOPMENT

We have been testing for over 20 years and have developed a range of standard and proprietary tests specifically applicable and correlated to how UL backpackers use their gear in the field. We have evaluated thousands of users reports from the field over the last 20 years, and we use this information to go our own way with setting standards.